Delivering Quality Solutions

to your bulk storage and

workplace safety issues

Uncompromising

high values

Integrity Support Solutions is the parent company for Storage Solutions and Industrial Safety Solutions. We provide industrial support services to the oil and gas industry and all heavy industrial and construction sectors.

This group of companies share consistent and uncompromising values of excellent customer service, high quality, flexible and innovative delivery with a “can do” culture.

We build long term relationships with our customers by being dependable and delivering the optimum solutions to your bulk storage and workplace safety issues.

Defining

the problem

delivering

the solution

Increasing

Productivity

by Reducing

Injuries

& Sickness

Helping you reduce workplace

related health costs

Protecting workers health & wellbeing

Industrial Safety Solutions specialise in occupational hygiene. We help our clients prevent workplace ill-health from exposure to chemicals, noise, vibration and biological contaminants.

Our services allow you to increase productivity by reducing workplace injuries and sickness which in turn can reduce insurance premiums. By providing expert, honest and independent advice, we can increase the trust between workers and management by helping you to ensure their welfare. We are active members of the British Occupational Hygiene Society (BOHS).

- COSHH Assessments

Risk Assessment

A risk assessment is the process of identifying hazards, evaluating risks and eliminating or controlling those hazards.

By law you have to complete risk assessments. The Management of Health and Safety at Work Regulations 1999 states that employers must identify any hazards and levels of risk to the health and safety of their employees while they’re at work.

ISS can carry out initial assessments to ascertain the potential health risks of operations carried out on clients’ sites and the possible route of entry for substances covered under the COSHH Regulations.

Substances monitored include chemical and biological agents following fully approved methodologies.

All subsequent sample analysis is completed by UKAS accredited laboratories.

Start eliminating risks now contact ISS.

- Bespoke Training

Bespoke Training

ISS offer client specific training packages, based upon site situations and operator scenarios, rather than using generic examples as this creates greater engagement and retention of learning.

We offer a range of topics and can tailor make a course to your requirements. Our most commonly requested topics have been:

- COSHH – Operator Awareness

- Understanding MSDS and COSHH Risk Assessments

- Health & Safety Training

Health & Safety Training

At ISS we have extensive experience of Health and Safety issues, and compliance, which we use to help our clients build a robust Health and Safety regime within their business.

We carry out a health and safety gap analysis from which we create a training programme designed specifically for you. The training is delivered on site, where possible, and can include:

- Accident investigation

- Asbestos safety

- Confined spaces

- COSHH

- Driver safety awareness

- DSE and Ergonomics

- Employee/safety representative

- Fire Safety

- First Aid including AED

- General H&S awareness

- Lone working

- Manual Handling

- Noise

- Office H&S awareness

- Permit to Work

- PPE/RPE

- Risk assessment

- Slips and trips

- Spill procedures

- Working at Height

To start the audit of your Health and Safety procedures and obtain bespoke training, contact us now.

- Hazardous Material

Surveys

Hazardous Material Surveys

ISS has extensive experience in completing hazardous materials surveys on a variety of sites to establish the extent of hazardous materials present, including mercury surveying and decontamination in the redevelopment of historic laboratories

We have the capability to sample and analyse for a wide variety of materials including chemical contaminants, radioactivity, fuel and oil spills and biological contaminants such as aspergillus and anthrax. We have completed surveys across a wide range of locations and scenarios, from arsenic contaminated stuffed animals in museums, to fume incidents in passenger aircraft and luxury yachts

And, we can provide an emergency service and give accurate and timely recommendations to establish the risks posed and ensure the safety of anyone coming into contact with these materials.

- Accident & Incident

Investigation Support

Accident & Incident Investigation Support

In the workplace, as in life, accidents and incidents occur. In the workplace it is important to investigate such events in order to learn and improve procedures to prevent any future incidents. It is equally important to identify any breaches of process or legal compliance.

We help in identifying the events that resulted in an accident or incident. We interview relevant personnel and inspect the location of the incident in order to clearly define the sequence of events that led to the episode taking place.

It is a requirement to notify the Health and Safety Executive in respect of any accident or incident as specified by the Reporting of Injuries, Diseases and Dangerous Occurrences Regulations (RIDDOR). ISS will assist with the reporting process. In addition, we assist with Personal Injury Claims.

Where appropriate, we will recommend what improvements to procedures need implementing to prevent any future incident.

The earlier we are involved the better.

- Workplace Noise

Assessment

Workplace Noise Assessment

The Control of Noise at Work Regulations (CNAWR) require an employer to make an assessment of noise exposure within their workplace, that the legal limits on noise exposure are not exceeded and that noise at source is reduced to a minimum. Also, health surveillance is required where there is a risk of hearing loss. ISS provide consultancy services to ensure that companies comply with the Regulations.

Noise surveys and personal dosimetry are conducted to monitor the noise levels and the duration of the exposure experienced by an employee.

We analyse this quantitative data and make recommendations on procedures and PPE that can be implemented to attenuate the noise, reduce exposure, protect employees and ensure compliance with the Regulations.

ISS has extensive experience in noise assessment in a wide range of businesses and industries, we just don’t like to shout about it.

- Indoor Air Quality

Indoor Air Quality

The quality of the air we breathe in our indoor environment can have effects on our health, wellbeing, performance and productivity.

Typical symptoms of poor air quality are eye irritation, headaches, fatigue, shortness of breath, coughing or sneezing through to an increased risk of diseases such as cancer and cardiovascular illness. Such issues are generally related to poor ventilation, dampness and the presence of bioaerosols.

At ISS we have experts in indoor air quality testing and assessment. We monitor sources of air particulates including VOCs (volatile organic compounds), Formaldehydes, CO2, NOX and SOX. We also assess for CO, fungal spores, and micro-organisms.

Our survey work is informed by appropriate standards such as COSHH, WELL Building Standards and RESET Air Standards.

To improve your indoor air quality contact us now.

- Local Exhaust

Ventilation Testing

Local Exhaust Ventilation Testing

According to the Health and Safety Executive’s Occupation Lung Disease Statistics in Great Britain 2019 there are 12,000 lung disease deaths each year linked to past exposures at work.

Local Exhaust Ventilation (LEV) testing by a competent person is a legal requirement in the UK. This is a 14-monthly imperative under Regulation 9 of the COSHH Regulations to inspect and test equipment to ensure the safety of your employees.

ISS conduct a detailed visual and structural assessment of LEV systems to establish if they are in working order, effective, maintained and in good condition.

We carry out measurements of LEVs to ascertain the performance of systems and ensure that they are controlling the of airborne contaminants.

Our reports are compliant with HSG258.

If your LEVs are coming up for inspection contact us now.

- Hand Arm/Whole Body

Vibration Exposure

Hand Arm/Whole Body Vibration Exposure

Hand–arm vibration (HAV) is caused by the use of work equipment and work processes that transmit vibration into the hands and arms of employees. Long-term, regular exposure to HAV is known to lead to permanent and debilitating health effects such as vibration white finger, loss of sensation and pain and numbness in the hands and arms. These effects are collectively known as hand-arm vibration syndrome.

An employer must ensure that his employees are not exposed to vibration above the Exposure Limit Value and if an ELV is exceeded he must take action to reduce exposure to below the limit value. If an Exposure Action Value is exceeded, then the employer must comply with the duty to reduce exposure to a minimum.

ISS will measure the vibration an operative is exposed to using a tri-axial accelerometer. From this we can extrapolate the amount of time it will take to reach the Exposure Action Value and Exposure Limit Value for the particular activity.

Where appropriate, we will advise on alternative work methods, workwear which can produce damping, equipment purchasing policy and maintenance procedures.

- Tank Declassification

Tank Declassification

The declassification of tanks which were previously in leaded gasoline service has considerable benefits in saving time and materials, but also in improved work efficiency and safety for operatives. There are strict regulations governing declassification.

ISS will ensure that you comply with the regulations by conducting survey work in which we will do a visual assessment of the tank and take samples to establish the nature and extent of personal and background exposures to organic and inorganic lead.

Our surveys can include:

- In-tank scale sampling, to assess the risk of lead exposure through skin absorption and ingestion.

- Air sampling, to assess the risk of lead exposure through inhalation.

- A visual assessment of the cleaned tank to confirm suitability for declassification

With ISS you can be confident you have the best partner to drive you on the road to successful declassification.

- Workplace Air

Monitoring

Workplace Air Monitoring

Exposure to gas and dust in the workplace can have a harmful effect on your workforce. If this is not controlled it can cause ill health. Some health effects may not manifest themselves for years after exposure.

The Control of Substances Hazardous to Health Regulations 2002 (COSHH) Regulation 7 places a duty on employers to stop or control the exposure of staff to dust and gases at work. In particular, Regulation 10 sets a duty to carry out workplace air monitoring to measure these exposures.

Our team of Occupational Hygienists will carry out a site visit to examine your operations and establish the nature of, and measure the extent of, personal and background exposure to substances hazardous to health.

We will present the results and, should action be required to improve the workplace air quality or conform to the legal obligations, make recommendations to reduce workplace exposure and achieve compliance.

Improving workplace air quality can improve morale and productivity.

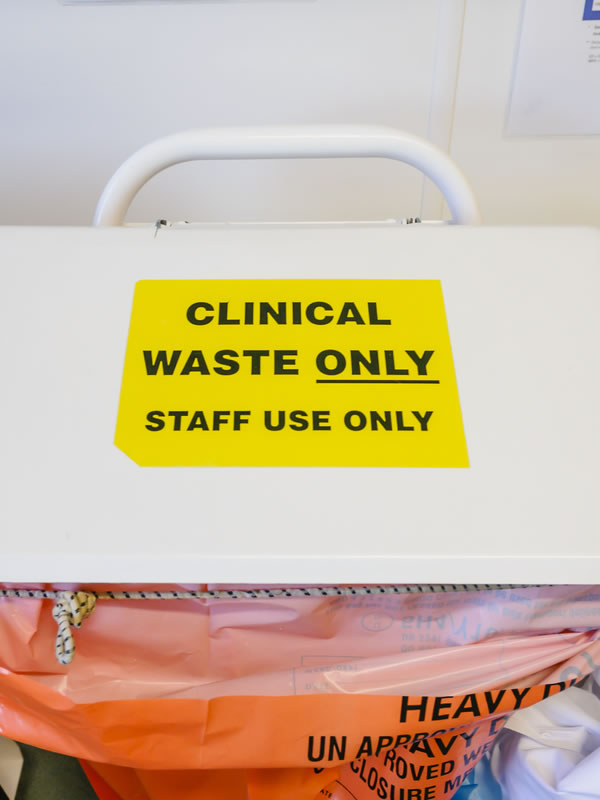

- Clinical Waste Process

Efficacy Testing

Clinical Waste Process Efficacy Testing

ISS is a leader in providing efficacy testing to establish whether clinical waste treatment plants are operating within the requirements of the Environment Agency Guidance.

We provide a full package of monitoring and laboratory services and have built up an enviable track record in providing these services for major waste management companies.

We have carried out validations and R&D work for Static Autoclaves, Rotoclaves, Steam Augers, Hot Oil augers, Cold chemical systems, Microwave disinfection units and numerous novel small scale technologies.

We also supply Biological Indicators and have developed our own Biological tracer suspensions for fugitive emissions testing.

Quality build, maintenance and repair of your storage tanks

We work on all types of storage tanks serving the bulk storage, power generation, distillery and food manufacturing sectors

We are an established leader in Storage tank construction & repair

Storage Solutions specialise in large scale bulk storage tank construction, repair and maintenance for the oil, energy, food, brewing and distilling industries.

Storage Solutions works in high risk environments and delivers bespoke solutions to challenging problems.

Our services include

- Project Management

- Principal Contractor under CDM regulations

- Welding

- Plating

- Pipe Work

- Structural Steelwork

- Tank Engineering & Design

- Labour Hire

Our principle tenet is the provision of high value, flexible service solutions for the UK Bulk Storage market. High value being responsive, high quality, on time delivery of maintenance solutions.

For tanks, steelwork and piping we conduct:

- Repairs

- Removal

- Reinstatement

- Modification

- Fabrication & assembly

- Instrumentation installation & repair

- Tank cleaning

- Hydro-static testing

- Non-destructive testing

Safety first is safety always

Safety and Quality are fundamental to us. Our Storage Solutions Integrated Management System ensures compliance with the rigorous criteria demanded by both ISO 14001 and ISO 9001.

We implement the highest standards for materials, manufacture and performance in everything we do. All tasks are subject to a systematic, recorded and communicated risk assessment procedure.

All our staff have appropriate medical and safety certification, whilst our management is IOSH and NEBOSH certified.

call us: 01683 222720 e: info@issg.ltd request a quotation